What Is Parametric Rolling in Container Ships?

When we think of large container ships, we picture massive vessels smoothly sailing across the sea, carrying thousands of goods. But every now and then, something unexpected happens that puts both the ship and its cargo at risk. That “something” is called parametric rolling. This dangerous movement can cause serious problems if it isn’t recognized and dealt with quickly. So, what is parametric rolling, and why is it so dangerous for container ships? Let’s break it down in a way that’s easy to understand.

What Is Parametric Rolling?

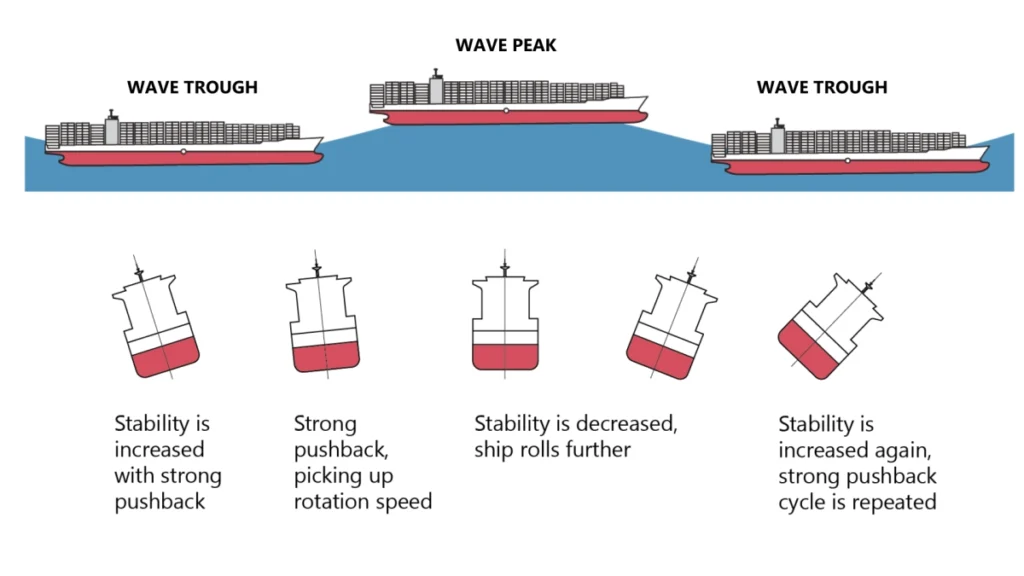

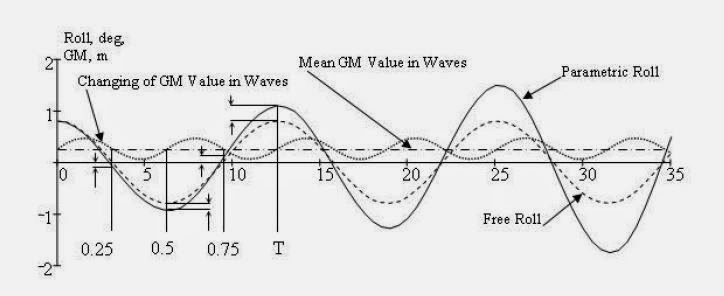

Parametric rolling is when a ship, especially a container ship, starts to rock back and forth from side to side. The rolling doesn’t stay small — it builds up, getting bigger and stronger over time. Think of it like being on a swing: if someone pushes you just at the right moment each time, you’ll swing higher and higher. That’s basically what happens to a ship during parametric rolling, except instead of a person pushing, it’s the waves doing the job.

This type of rolling is special because it doesn’t happen all the time. It takes the right kind of waves, hitting the ship at the right angle, to trigger it. Once it starts, though, it can happen fast, in a matter of minutes, and the rolling can become severe enough to cause serious problems.

How Parametric Rolling Differs from Other Ship Rolling

To understand parametric rolling better, it helps to know how it’s different from other kinds of rolling. All ships experience some rolling, especially in rough weather. Normal rolling is when the ship gently rocks with the motion of the waves. It’s like sitting in a rocking chair: it may sway back and forth, but the movement usually stops after a while.

Parametric rolling is different because it doesn’t just happen naturally. It’s caused by specific waves coming at certain angles. And unlike regular rolling, where the ship’s movement tends to slow down, parametric rolling makes the ship move more and more until it becomes dangerous. While normal rolling might feel like a slow rocking chair, parametric rolling is more like an out-of-control ride that keeps getting worse if nothing is done to stop it.

Causes and Factors Behind Parametric Rolling

So, what exactly causes parametric rolling? There are a few important factors that come together to create this problem:

- Wave Height and Pattern: The size and shape of the waves matter a lot. Large waves, especially those that come in regular patterns, can cause the ship to start rolling. It’s almost like the waves are hitting the ship at just the right time to push it more and more each time.

- Ship Speed: How fast the ship is going also plays a big role. If a ship is moving too quickly or slowly through certain types of waves, it can increase the risk of parametric rolling. Adjusting the speed can often help stop the rolling from getting worse.

- Ship Design: Not all ships are likely to experience parametric rolling. Long and narrow ships, like container ships, are more at risk. Their length means that they can catch waves in ways that cause more rocking. It’s a bit like how certain types of swings move differently based on how long the ropes are.

These three things—waves, speed, and ship design—all work together to make parametric rolling more likely to happen.

Effects on Ship Stability and Cargo

The biggest danger of parametric rolling is how it affects the ship’s stability. A ship needs to stay balanced in the water to move safely. But when parametric rolling happens, the ship starts to lean more and more to one side, which can throw off that balance.

If parametric rolling gets bad, the ship could tip over, which is called capsizing. While modern container ships are designed to prevent this, there’s still a real danger if the rolling isn’t stopped quickly.

Parametric rolling also affects the cargo on board. Container ships carry stacks of large containers, and if the ship rolls too much, those containers can shift or even fall overboard. Imagine a tall stack of boxes leaning too far and toppling over — that’s exactly what happens during severe parametric rolling. This can lead to millions of dollars in losses, not to mention the environmental risk if dangerous cargo spills into the ocean.

Warning Signs and Early Detection

Parametric rolling often gives off warning signs before it gets out of hand. Ships have systems and sensors that detect changes in how the ship is moving, and these systems help alert the crew when rolling is becoming a problem. But even without advanced tech, there are a few things the crew can watch out for:

- Sudden Changes in Waves: If the waves start to rise or fall in a way that seems unusual, it could be a sign that parametric rolling is about to start. The key here is noticing when waves seem to come in patterns or when they start swelling up more than expected.

- Excessive Tilting: If the ship starts leaning to one side more and more after each wave, it’s a clear sign that parametric rolling is developing. Paying attention to these subtle shifts can give the crew time to respond before things get worse.

Early detection is crucial because it allows the crew to take steps to stop the rolling before it gets too dangerous.

Prevention Methods and Technology

Stopping parametric rolling once it starts can be tricky, but there are some tried-and-true methods for prevention. One of the simplest and most effective solutions is adjusting the ship’s speed and direction. By slowing down or changing course, the crew can reduce the effect of the waves and stop the rolling from getting worse.

There are also stabilizers that can be installed on ships to help keep them steady. These are usually fins or other devices that adjust automatically to counterbalance the ship’s movement. Think of them like the wings on an airplane that help it stay level.

On top of that, modern ships use software that tracks sea conditions and warns the crew if parametric rolling is likely to happen. This gives the crew time to make changes before they hit rough seas. It’s like having a weather app for the ocean that tells you when to expect dangerous waves.

Weather Forecasting and Risk Reduction

Weather plays a huge role in parametric rolling, which is why weather forecasting is so important for container ships. Before setting out on a voyage, the crew checks sea conditions to see if there’s a risk of tall waves that could cause problems. This is especially important if the ship is going to pass through areas known for rough seas.

Advanced weather systems can now predict wave heights and patterns accurately. By keeping an eye on these forecasts, crews can avoid areas where the risk of parametric rolling is high. Just like you might check the weather before going on a road trip, ships use these forecasts to plan their routes and avoid trouble.

Case Studies of Parametric Rolling Incidents

Parametric rolling isn’t just a theoretical problem — there have been real incidents where this dangerous phenomenon has caused significant damage and loss. Let’s look at a couple of well-documented cases where parametric rolling led to major issues for container ships.

Case 1: APL China Incident (1998)

One of the most famous cases of parametric rolling involved the APL China, a large container ship that faced severe rolling while crossing the Pacific Ocean in 1998. The ship was caught in a powerful storm with waves reaching up to 40 feet. The combination of the wave pattern, the ship’s speed, and its long, narrow design created the perfect conditions for parametric rolling to develop.

Within a short time, the ship started rocking dangerously from side to side. Despite efforts to stabilize it, the rolling intensified, and containers began to shift and break free. The APL China lost over 400 containers overboard, and another 800 containers were damaged beyond repair. The financial loss was enormous, reaching millions of dollars, not to mention the environmental impact of containers lost at sea.

Thankfully, the crew was able to keep the ship from capsizing, but this incident became a wake-up call for the shipping industry about the dangers of parametric rolling. Since then, many shipping companies have adopted stricter safety measures to prevent similar incidents.

Case 2: MSC Napoli (2007)

In 2007, the MSC Napoli, a container ship, was severely damaged off the coast of the UK after being caught in rough seas. The ship experienced parametric rolling during a heavy storm in the English Channel. The rolling grew worse with each wave, and despite the crew’s efforts, the ship began to take on water and eventually suffered structural damage.

As a result of the rolling and damage, the captain made the decision to ground the ship near the coast to prevent it from sinking. While no containers were lost at sea in this case, over 100 containers had to be salvaged from the grounded ship. The cost of the salvage operation and the damage to the cargo was extensive, and it took months to fully recover the ship and its goods.

This incident highlighted the dangers of parametric rolling, even in areas close to shore, and showed how quickly conditions can change during storms. The MSC Napoli case reinforced the need for advanced forecasting tools and real-time monitoring systems to prevent parametric rolling from causing similar accidents in the future.

Case 3: MOL Comfort (2013)

Another well-known incident occurred with the MOL Comfort in 2013. This container ship broke apart in the Indian Ocean due to severe weather conditions and parametric rolling was one of the contributing factors. The ship split in two, resulting in the loss of over 4,000 containers. Fortunately, the crew was rescued, but the ship and its cargo were lost.

While the structural failure of the MOL Comfort was primarily blamed on design flaws, parametric rolling played a role in putting immense stress on the ship’s structure. The disaster led to further studies on how ships should be designed to withstand the dangerous combination of rolling and heavy seas.

These case studies underline the severe impact parametric rolling can have on container ships. From losing hundreds of containers to suffering massive structural damage, these incidents remind us of the importance of detecting and preventing this dangerous phenomenon early on.

Regulations and Safety Standards

Because parametric rolling is such a serious threat, there are international regulations in place to make sure that container ships are built and operated safely. One of the main organizations that sets these rules is the International Maritime Organization (IMO). They create guidelines that cover everything from ship design to how crews should handle emergencies like parametric rolling.

Ships are also regularly inspected to make sure they meet safety standards. These inspections are important for catching any issues that might make a ship more vulnerable to parametric rolling, like structural problems or faulty equipment.

By following these regulations and maintaining safety standards, shipping companies can reduce the risk of parametric rolling and keep both the crew and cargo safe.

Conclusion

Parametric rolling may sound complicated, but at its core, it’s about understanding how waves and ships interact in a dangerous way. By knowing what causes it, how to spot it, and how to prevent it, container ships can stay safe even in rough seas.

Whether it’s adjusting speed, changing course, or using modern technology, there are many ways to reduce the risk of parametric rolling. And with strict regulations and safety standards in place, the shipping industry is working hard to make sure this dangerous phenomenon doesn’t cause major problems.