What Are Pipe Laying Ships?

Imagine you need to build a super-long pipeline under the ocean to move oil or gas from one place to another. How would you do it? That’s where pipe laying ships come in! These are massive, high-tech vessels designed specifically to carry and install pipelines deep under the sea. Let’s dive in and learn more about how these incredible ships work and why they’re so important.

What Does Pipeline Laying Mean?

Pipeline laying is exactly what it sounds like: placing pipes on the seafloor to transport materials like oil, gas, or even water. Think of it like building a road, but instead of asphalt, you’re working with huge pipes. And instead of land, you’re dealing with the ocean floor. These pipelines connect offshore drilling platforms to processing plants or storage facilities on land.

What Is the Pipe Laying Procedure?

The process of laying pipes underwater involves the use of pipeline vessels, and it isn’t as simple as just dropping them into the ocean. It’s a carefully planned operation that happens in steps:

- Preparing the Site: Engineers first map out the seabed to make sure it’s safe and stable for laying pipes. They look for obstacles like rocks or uneven terrain.

- Welding the Pipes: Onboard the ship, workers weld sections of pipe together into one long line. Each weld is checked to make sure it’s strong enough to handle the deep-sea pressure.

- Lowering the Pipe: As the ship moves forward, the pipe is gently lowered into the water. Special machines make sure it doesn’t bend or break as it sinks to the seabed.

- Securing the Pipeline: Once the pipe is in place, it’s sometimes covered with rocks or concrete to keep it steady and protect it from currents or other underwater hazards.

What Are the Different Types of Pipe Laying?

There are a few different ways to lay pipes underwater, depending on how deep the water is and the conditions of the seabed. Here are the most common methods:

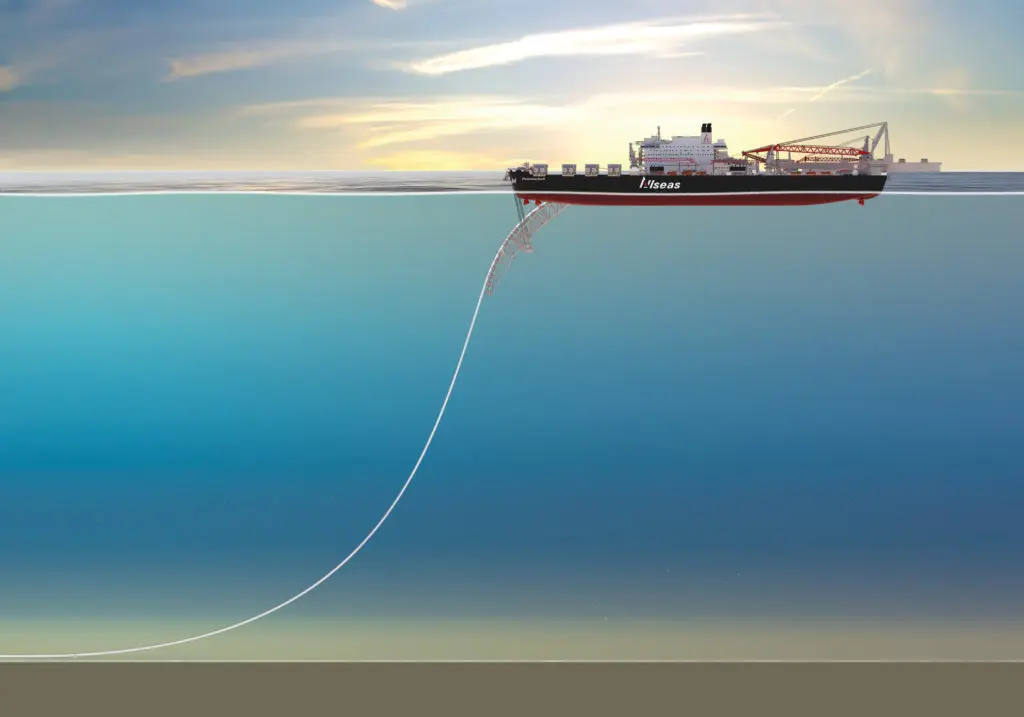

- S-Lay: The pipe forms an “S” shape as it’s lowered from the ship to the seabed. This method is great for shallow and moderate depths.

- J-Lay: The pipe forms a “J” shape, making it ideal for deep waters because it puts less stress on the pipe.

- Reel-Lay: Pipes are pre-welded and wound onto a giant reel on the ship. When it’s time to install them, the ship unrolls the pipe like a spool of thread. This is one of the fastest methods.

Key Components of a Pipe Lay Vessel

Pipe laying ships are like floating factories. They’re packed with special equipment to get the job done. Here are some of the key components:

- Stinger: A long structure that extends from the back of the ship, guiding the pipe as it’s lowered into the water.

- Tensioners: Machines that hold the pipe tightly to prevent it from slipping or bending while it’s being laid.

- Dynamic Positioning System (DPS): A high-tech system that keeps the ship perfectly still, even in rough waters. It uses powerful thrusters and GPS to stay in place.

- Welding Stations: Onboard facilities where workers join sections of pipe together.

How Does a Pipe Laying Vessel Work?

Picture this: a pipe laying ship is like a giant sewing machine. It welds, supports, and gently feeds the pipe into the ocean as it moves forward. The ship’s dynamic positioning system keeps it steady while the tensioners control how the pipe is lowered. Workers monitor everything from control rooms, ensuring the pipe lands exactly where it’s supposed to.

Features and Characteristics of Pipelayer Ships

Pipe laying ships are massive and incredibly advanced. Here are some of their standout features:

- Size and Stability: These ships are huge, often as long as football fields, to carry miles of pipeline.

- Onboard Technology: They’re equipped with advanced sensors, welding machines, and monitoring systems to handle complex jobs.

- Crew Accommodation: Since these projects can take weeks or months, the ships have living quarters for the crew, complete with kitchens, gyms, and even recreational areas.

Dynamic Positioning in Pipe Laying

Dynamic positioning (DP) is like autopilot for ships, but way more advanced. Instead of dropping an anchor, DP systems use thrusters and GPS to keep the ship in the exact position it needs to be. This is critical when you’re lowering heavy pipes into the ocean, as even a small drift could cause the pipe to land in the wrong spot.

Safety on Pipe Laying Ships

Safety is a big deal on pipe laying ships because the work is so complex and often dangerous. Here are some of the precautions taken:

- Regular Inspections: All equipment is checked frequently to ensure it’s working properly.

- Training: Crew members go through extensive safety training to handle emergencies.

- Protective Gear: Workers wear helmets, gloves, and other safety equipment to reduce risks.

Frequently Asked Questions

How long are the pipes?

The pipes can be hundreds of miles long once all the sections are welded together.

How deep can these ships lay pipes?

Modern pipe laying ships can work in water depths of over 3,000 meters (about 10,000 feet).

Are these ships used for anything else?

Some pipe laying ships can also install cables for telecommunications or power.

Conclusion

Pipe laying ships are incredible pieces of engineering that play a vital role in connecting the energy we use every day. From their high-tech components to the precise procedures they follow, these vessels make it possible to install pipelines deep under the sea. Next time you hear about offshore energy, you’ll know the unsung heroes behind it—pipe laying ships!