What Is Dynamic Positioning Ship?

Dynamic positioning (DP) is an advanced technology that helps certain ships hold their position on the open sea without an anchor. Imagine you’re floating in the middle of the ocean, and the waves and wind are constantly pushing your ship in different directions. A DP system takes control of the ship’s engines, thrusters, and propellers, adjusting them in real-time to keep the ship steady in one spot.

Ships that use DP are often involved in specialized work like drilling, undersea construction, or marine research—things that need precision. DP is a modern solution for tasks that used to rely on anchors, especially in deep waters where anchoring just isn’t practical. This article explores why DP is used, how it works, and where you’ll find it in action.

Why Is Dynamic Positioning Used?

In some marine operations, holding a precise position is crucial. Here’s why DP systems are so valuable:

- Deep-Water Stability: In deep water, anchoring can be impossible or unreliable. A DP system keeps ships stable without the need for a heavy, expensive anchor.

- Safe and Precise Operations: For jobs like oil drilling or underwater construction, even a slight movement can cause problems. DP allows ships to stay perfectly still, so these operations can proceed without interruptions.

- Environmental Protection: Anchors can damage coral reefs and ocean habitats. Using DP, ships can hover in place without dropping an anchor, which helps protect fragile environments.

- Versatile Movement: DP systems allow ships to stay steady and move flexibly if needed. This can be important for research vessels that might need to adjust their position without breaking away entirely from one area.

- Weather and Current Adaptation: A DP system can keep a ship steady even with changing wind, waves, and currents. It continually adapts, so the ship stays where it’s needed.

How Does Dynamic Positioning Work on Ships?

Dynamic positioning combines several systems working together, like a finely tuned orchestra, to keep the ship still. Here’s how it breaks down:

- Monitoring the Environment: The DP system gathers data from sensors that measure factors like wind speed, wave height, and currents. It knows what forces are acting on the ship.

- Adjusting to Changes: Based on the data, the DP system calculates how to counteract these forces. It sends instructions to the thrusters, propellers, and engines, telling them how much power to apply and in which direction.

- Staying in Place: The engines and thrusters make tiny movements to keep the ship in one spot. If the wind shifts or waves get stronger, the DP system adjusts instantly. This continuous back-and-forth keeps the ship steady.

Applications and Use Cases of Dynamic Positioning in Industries

Dynamic positioning is used in a variety of industries, each with unique needs for stability and precision. Here are some key areas where DP is essential:

- Oil and Gas Exploration: DP systems keep drilling vessels steady while extracting oil and gas. Anchoring isn’t practical in deep-water drilling, so DP is a safe and effective alternative.

- Underwater Research and Exploration: Ships studying marine life or mapping the ocean floor rely on DP to stay steady. Researchers can gather accurate data without worrying about drifting.

- Construction Projects at Sea: DP is crucial for installing offshore wind turbines and laying undersea cables. These ships need to stay precisely in place to carry out construction in deep water.

- Luxury Yachts and Cruises: High-end yachts and some luxury cruise ships use DP to stay in beautiful spots without dropping an anchor, which can damage marine habitats.

DP Vessel Types: DP1, DP2, and DP3 Explained

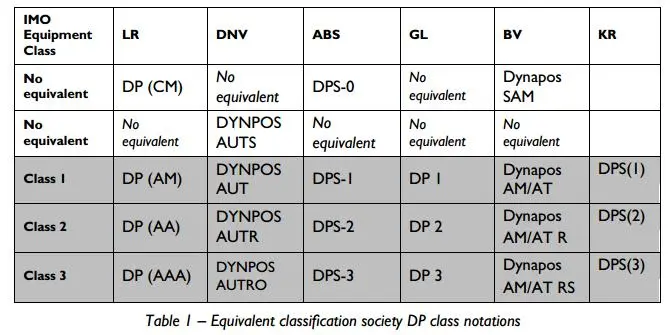

Dynamic positioning systems come in three main types, each suited to different levels of reliability and risk:

- DP1: This is the basic level of DP. DP1 vessels have no backup systems, so if something fails, they might lose position. DP1 is suitable for simpler tasks in calmer waters, where staying in position isn’t as critical.

- DP2: DP2 vessels have a backup for each key system, so if one part fails, another can take over. This extra reliability makes DP2 a common choice in industries where stability is essential but not at the highest level of risk.

- DP3: The highest level, DP3, has multiple backups for maximum reliability. These vessels are used in high-risk operations like deep-sea drilling. Even if several systems fail, a DP3 ship can maintain its position safely.

Dynamic Positioning System Components

Each DP system has several important parts working together. Let’s break down the key components:

- Power: A reliable power source is crucial. The DP system, thrusters, and other machinery need continuous power to keep the ship in position.

- Thrusters: These small propellers push the ship in different directions, countering waves and wind. DP systems control the thrusters with precision, making tiny adjustments to maintain stability.

- Environmental Sensors: These measure the forces acting on the ship, like wind speed, water currents, and wave direction. The DP system uses this data to decide how to respond.

- Position Reference Sensors: GPS and other tools help the DP system understand where the ship is in relation to its target spot, making sure it stays exactly where it should.

- DP Controller: This is the ship’s “brain,” processing data from sensors and deciding on the best adjustments to make with the thrusters and engines.

- Hardware (HMI): The human-machine interface (HMI) is the control panel where the operator can monitor the system and make manual adjustments if needed.

- DP Operator: The human operator monitors the DP system and steps in if anything unusual happens. DP operators are trained to handle complex issues and keep operations safe.

What Is the Difference Between DP Controller and DP Operator?

The DP controller is the system’s brain, analyzing data and giving instructions to the ship’s engines and thrusters. It’s automated, adjusting in real-time without human help.

The DP operator, on the other hand, is the trained professional watching over the system. They step in to troubleshoot or make decisions if there’s a problem or if the system needs human input.

Case Studies of DP Failures

- A diving support vessel experienced a “large excursion” failure due to a partial loss of power, which compromised the DP system’s accuracy. In this case, the issue stemmed from a breakdown in communication between position reference systems and DP control. This failure posed significant risks to divers underwater who depended on the vessel’s stability. This incident underscored the need for DP systems with high redundancy, especially in hazardous operations involving human lives

- In another case, a DP vessel lost position control due to a total blackout while operating in adverse weather. The vessel drifted off position as waves and strong currents overwhelmed its capabilities to maintain location without power. Emergency recovery procedures were delayed, exacerbating the drift-off distance. This case emphasized the vulnerability of DP systems in severe weather conditions and highlighted the importance of backup power and robust recovery protocols during DP operations.

Certification and Standards in Dynamic Positioning

To ensure DP systems work safely and reliably, there are specific certifications and standards in place. The International Maritime Organization (IMO) and the Nautical Institute are two main bodies that set these standards.

For example, DP operators often need certification from the Nautical Institute, which involves training and passing exams. Following standards helps keep operations safe and ensures that DP systems work as they should.

Pros and Cons of Dynamic Positioning

Pros:

- Precision: DP lets ships stay exactly in place, ideal for complex operations.

- Environmental Protection: DP systems eliminate the need for anchors, which can damage ocean habitats.

- Adaptability: DP allows ships to hold position in deep waters and rough conditions, where anchors aren’t practical.

Cons:

- High Cost: DP systems are expensive to install and maintain.

- Fuel Consumption: DP systems use a lot of fuel, which can be costly and have environmental impacts.

- Risk of Failure: While DP systems are advanced, failures can still happen, and losing position mid-operation can be risky.

Frequently Asked Questions

- How reliable are Dynamic Positioning Systems during severe weather?

DP systems are usually reliable, but severe weather can still be challenging. DP3 ships are better equipped to handle extreme conditions, thanks to their backup systems.

- What happens if a dynamic positioning system fails mid-operation?

If the DP system fails, the operator takes over. Backup systems can sometimes help, but if a ship loses its position completely, it may need to halt operations until the problem is fixed.

- How do Dynamic Positioning Systems compare to traditional anchoring?

DP is more flexible than anchoring, especially in deep water, where anchors can’t reach the bottom. DP also avoids the environmental damage caused by anchors.

- What is the cost of operating a DP System on a vessel?

Operating DP can be costly due to high fuel and maintenance costs, but the precision and safety benefits make it worthwhile in certain industries.

- Are there environmental impacts of using Dynamic Positioning Systems?

While DP requires more fuel, it’s often a better choice for sensitive marine environments since it doesn’t disturb the seabed or damage habitats like coral reefs.

Conclusion

Dynamic positioning technology is transforming the maritime industry, making it possible for ships to hold position without an anchor, even in the middle of the ocean. From oil rigs to research vessels, DP systems allow precise and safe positioning that opens up new possibilities. While there are challenges, the benefits of DP make it a valuable tool in today’s marine operations.