What Is Steam System? How Does It Work?

Steam systems are like the hidden engines of a ship. They create and use steam to power large vessels, keep them warm, and even run other essential equipment onboard.

This article will walk you through what a steam system is, why it’s so important for ships, and how each part works together to keep the vessel moving and operating smoothly.

Overview of Steam Systems in Maritime

A steam system on a ship is a setup that heats water until it turns into steam. This high-pressure steam then powers various systems on the vessel. Steam systems are key in some ships for:

- Propulsion: Moving the ship forward.

- Heating: Warming different parts of the ship.

- Operating equipment: Powering support systems like pumps and generators.

Steam systems are found in various types of vessels, from older ships that relied fully on steam to modern ships that still use steam for certain parts. While these systems are sometimes replaced by newer engines, steam systems are still reliable and effective, especially on large ships.

History of Steam Systems on Ships

The use of steam power on ships dates back to the early 19th century. Initially, steamships relied on large paddle wheels that were powered by steam-driven engines, allowing ships to move even without wind, unlike traditional sail-powered vessels.

Over time, the industry shifted from paddle wheels to screw propellers, which offered greater efficiency and control. These advancements made steam systems highly popular, enabling ships to travel faster, farther, and with greater reliability.

While newer engine types are now common, steam technology is still used on certain large vessels, maintaining its legacy in maritime history.

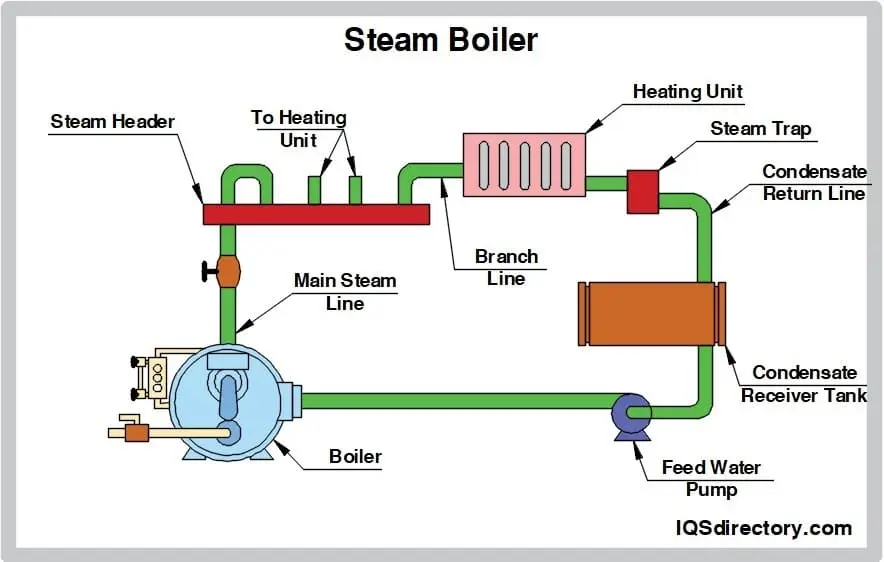

Main Components of a Maritime Steam System

A steam system is made up of several main parts, each doing an important job:

- Boiler: The heart of the steam system where water is heated until it turns into steam.

- Turbine: A machine that spins when steam passes through it, turning that energy into mechanical power.

- Condenser: This cools down the steam after it’s been used, turning it back into water.

- Pipes and Valves: These guide and control the flow of steam throughout the system.

Each of these components works in a cycle: water heats up in the boiler, turns into steam, moves through the turbine to provide power, cools back into water in the condenser, and goes back to the boiler.

This cycle repeats as long as the system is running, making it efficient and powerful.

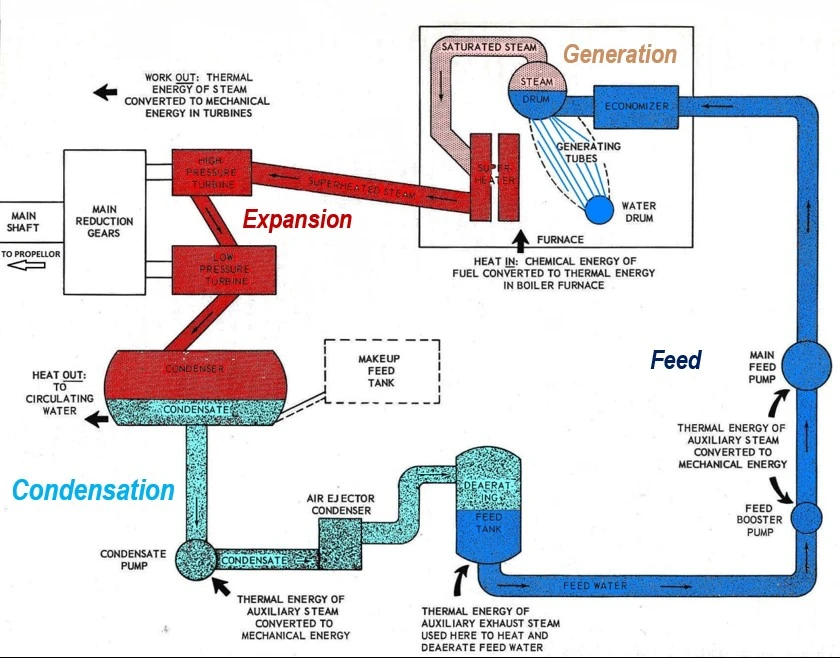

How Does a Steam System Work on a Ship?

To understand how a steam system works, it helps to look at each step in the process:

- Heating the Water: The boiler heats water, turning it into high-pressure steam.

- Powering the Turbine: The steam moves through pipes to the turbine. As the steam hits the turbine blades, it makes them spin, generating the power that moves the ship.

- Condensing the Steam: After leaving the turbine, the steam cools down in the condenser and turns back into water.

- Recycling the Water: The water goes back to the boiler, and the cycle starts again.

This process means the steam system doesn’t waste much energy, as the water is reused in each cycle.

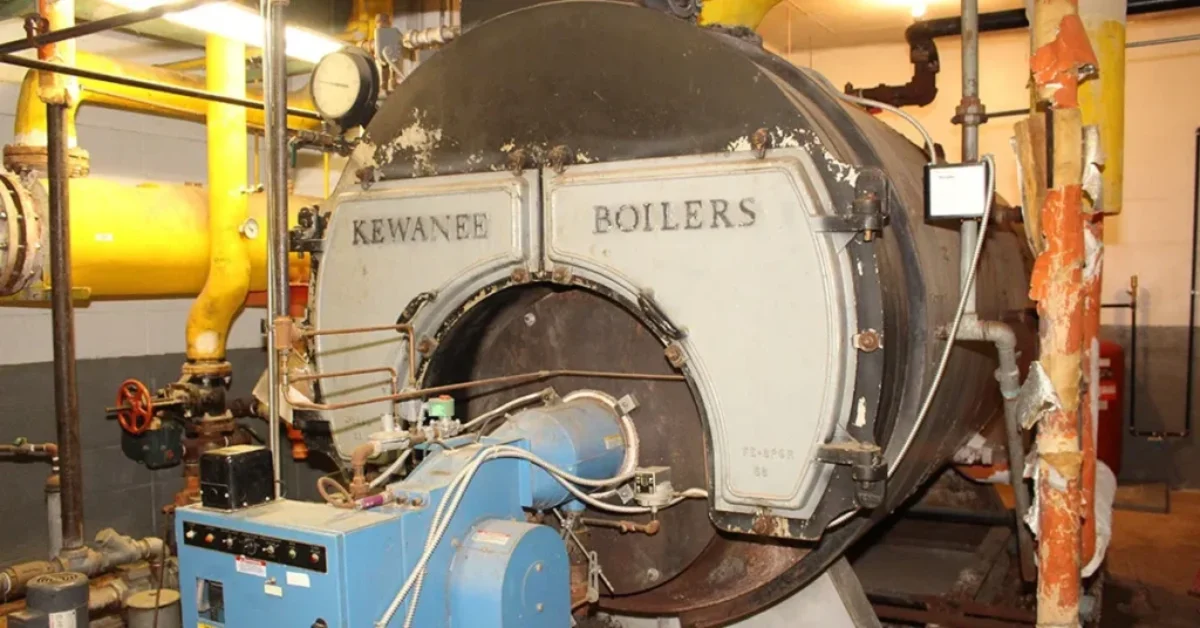

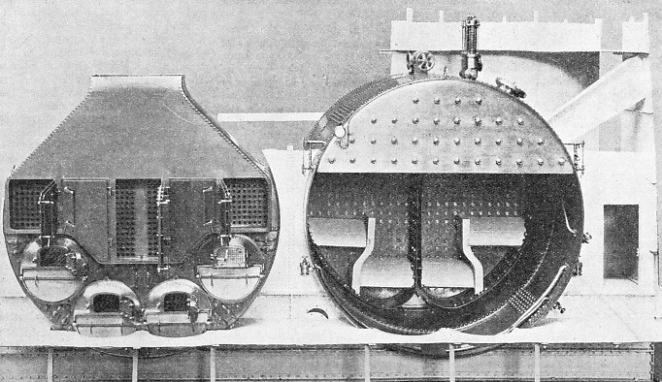

Types of Ship Boilers

Not all boilers are the same. Different ships may use different boiler types based on what they need. Some of the common types are:

- Fire-Tube Boilers: In these, hot gases from the burner pass through tubes that are surrounded by water. They’re simpler in design and often used in older or smaller ships.

- Water-Tube Boilers: These boilers work the opposite way: water flows through tubes surrounded by hot gases. They can handle higher pressures, making them popular in modern steam systems.

- Exhaust Gas Boilers: This type recycles exhaust gases from the ship’s engine to heat the water, saving fuel and energy.

Each type of boiler has its advantages, and the right choice depends on the ship’s size, purpose, and efficiency needs.

Boiler Operation and Steam Generation

At the heart of a steam system is the boiler, which serves as the “kitchen” where steam is made.

Fuel, typically oil, burns in the boiler’s burner, producing a hot flame that heats the water inside.

As the water reaches high temperatures, it turns into steam under pressure. This pressurized steam is then directed through the ship’s system, where it provides power and heat.

The boiler’s design allows for efficient steam production, keeping the cycle running as long as the system is active. This process ensures a continuous supply of steam, which is crucial for the ship’s operations.

The Steam Cycle

The steam cycle is an ongoing loop that keeps the system working efficiently.

- Steam is Generated: The boiler heats the water, turning it into high-pressure steam.

- Steam Travels to the Turbine: This steam flows to the turbine, where it provides power.

- Steam Cools in the Condenser: After leaving the turbine, the steam cools down and turns back into water.

- Water Returns to the Boiler: This cooled water flows back to the boiler to start the cycle again.

This recycling process is key because it means the system uses less water and less energy overall.

Steam Turbines and Ship Propulsion

Steam turbines are the main powerhouse for ship propulsion in a steam system.

When high-pressure steam flows into the turbine, it hits a series of blades, causing them to spin.

This spinning action creates the energy needed to turn the ship’s propeller. As the propeller rotates, it pushes against the water, driving the ship forward.

This method of propulsion is especially efficient for large ships that need substantial, steady power to move through the water. The entire system works smoothly to provide a reliable source of propulsion over long journeys.

Steam for Ship Heating and Auxiliary Systems

In addition to propulsion, steam is used to power a variety of other systems on a ship.

For example, steam is often directed to heating systems that warm the crew’s quarters, keeping the living areas comfortable even in cold environments.

Steam is also utilized for other daily functions, such as powering kitchen appliances and laundry equipment, which are essential for crew operations on long voyages.

Furthermore, steam can be used to operate certain pumps, generators, and other equipment, making it a versatile and valuable resource for various needs on board.

Safety in Steam System Operations

Operating a steam system safely is crucial, as steam is extremely hot and under high pressure. Ships are equipped with safety features designed to manage the risks associated with steam.

For instance, safety valves are in place to release excess steam if the system’s pressure gets too high, preventing possible explosions.

Pressure gauges allow crew members to monitor the system closely and respond quickly if pressure levels become unsafe.

In emergency situations, some steam systems also have automatic shutdowns, which can activate to protect the crew and the ship. With these safety measures and proper training, crews are well-prepared to manage the steam system effectively.

Steam System Maintenance and Inspection

Maintaining a steam system involves regular inspections and care to ensure it operates smoothly and safely.

Inspections help detect any wear, leaks, or corrosion that could lead to bigger problems if left unchecked.

Cleaning the system and applying lubrication to moving parts are standard procedures that keep the equipment running efficiently.

When parts become worn out, timely replacements prevent breakdowns and ensure that the system remains in optimal condition.

With routine maintenance and attention to detail, a steam system can remain reliable for extended periods, supporting the ship’s daily needs.

Benefits of Steam Systems on Ships

Steam systems offer several key advantages for large ships. First, they provide steady and powerful propulsion, which is ideal for vessels that require reliable, continuous power on long journeys.

Steam systems are also efficient in terms of water use, as the water is continuously recycled within the system.

Additionally, these systems are known for their durability and long lifespan, making them a reliable choice for certain types of vessels.

Despite the advancements in modern technology, steam systems remain a practical and efficient option in the maritime industry.

Challenges of Using Steam Power

Despite their advantages, steam systems come with a few challenges. They can be fuel-intensive, which increases operational costs, especially with rising fuel prices.

The heavy-duty materials required to build and maintain steam systems add significant weight to the ship, which can affect overall efficiency.

Additionally, steam systems require specialized training for crew members, as mishandling high-pressure steam can lead to dangerous situations. These factors make steam systems less ideal for smaller or newer vessels that may prioritize fuel efficiency and lighter designs.

Alternatives to Steam in Maritime

Many ships today use alternative power sources to steam. Some popular options include:

- Diesel Engines: Diesel engines are fuel-efficient and often easier to maintain than steam systems. They’re commonly used in commercial ships.

- Electric and Hybrid Systems: Some ships are experimenting with electric or hybrid power, which can reduce fuel use and environmental impact.

- Gas Turbines: These are powerful, like steam turbines, but are often smaller and lighter.

These newer options are especially popular for smaller ships or ships focused on energy efficiency.

Conclusion

Steam systems have been a critical part of maritime history, helping ships travel faster and farther. Today, while some newer technologies are making their way into the industry, steam systems remain a powerful and reliable choice for many large vessels.

With their ability to generate strong, steady power and support multiple systems on a ship, they continue to be an essential piece of maritime engineering.