What Is a Ballast Water Treatment System? How Does It Work?

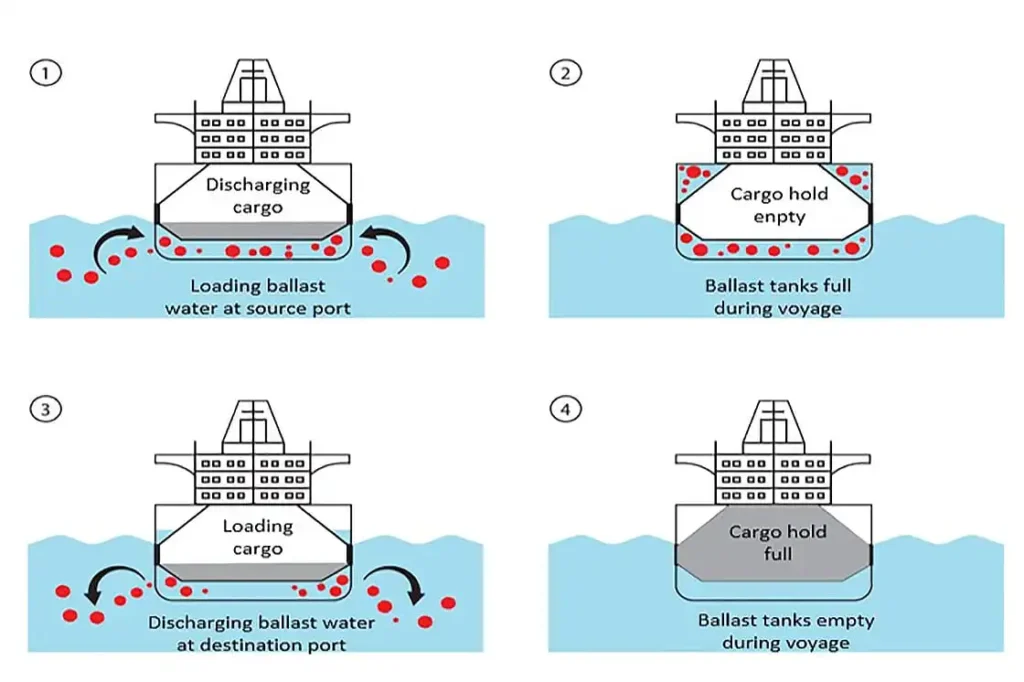

Ships use ballast water to stabilize themselves during voyages. However, this water often contains small marine organisms that can pose a threat to ecosystems when the ballast is discharged into different waters. To tackle this issue, ships are required to use ballast water treatment systems, which help eliminate these harmful organisms and protect the marine environment.

But what exactly is a ballast water treatment system, and how does it work? In this article, we’ll break down everything you need to know about these systems, the key technologies involved, and what factors are considered when choosing one for a ship.

What Is a Ballast Water Treatment System?

A ballast water treatment system is a setup designed to clean or neutralize harmful organisms that might be carried in the ballast water of a ship. Ballast water is essential for maintaining stability, especially when a ship is lightly loaded. However, this water often contains various organisms that, if released into different marine environments, can cause serious ecological damage.

Ballast water treatment systems help prevent the spread of these invasive species by treating the water before it’s discharged into the ocean. The goal is to eliminate the organisms in the ballast water, ensuring that only clean, safe water is released back into the marine ecosystem.

How Does a Ballast Water Treatment System Work?

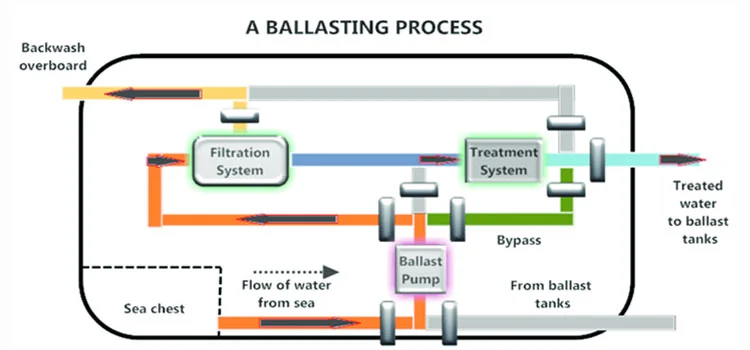

Ballast water treatment systems generally rely on two processes: filtration and disinfection.

- Filtration: As ballast water is pumped into the ship, it’s passed through a filtration system to remove larger particles, like sand, plankton, or small marine organisms. This is the first step in ensuring that the water is cleaned before being stored in the ship’s ballast tanks.

- Disinfection: After filtration, the water is treated to kill or neutralize smaller, microscopic organisms, such as bacteria and viruses. Disinfection methods vary, from UV light to chemical treatments and even electric pulses, but the goal is always the same.

Together, these processes make the ballast water safe for release back into the ocean without posing a risk to local ecosystems.

Technologies in Ballast Water Treatment

Ballast water treatment systems use a variety of technologies to achieve effective treatment. Some systems combine multiple methods, while others rely on a single, robust technology. Below are the main technologies used in ballast water treatment:

- Filtration Systems (Physical)

Filtration is a common first step in ballast water treatment. These systems work like a sieve, removing large particles and organisms from the water. However, filtration alone can’t eliminate bacteria and viruses, which is why it’s often combined with other disinfection methods. The primary goal of filtration is to prepare the water for further treatment.

- Chemical Disinfection (Oxidizing and Non-Oxidizing Biocides)

Chemical disinfection involves adding chemicals to the water to kill organisms. There are two main types:

- Oxidizing biocides: These chemicals, such as chlorine, react with organic material in the water, destroying harmful organisms.

- Non-oxidizing biocides: These chemicals work by disrupting key biological processes in the organisms, effectively killing them.

Though effective, chemical treatments require careful monitoring to ensure the treated water is safe for discharge.

- Ultra-Violet (UV) Treatment

UV treatment is an environmentally friendly option that uses ultraviolet light to kill or deactivate microorganisms by damaging their DNA. It’s particularly effective for clear water since UV light can penetrate and affect the organisms efficiently.

This method avoids the use of chemicals, but its effectiveness can be reduced in murky or sediment-laden water.

- Deoxygenation Treatment

Deoxygenation systems work by removing oxygen from the ballast water, suffocating organisms that need oxygen to survive. It’s a chemical-free process and is considered eco-friendly, though it can take longer to be fully effective compared to other methods.

- Heat (Thermal Treatment)

Thermal treatment involves heating the ballast water to temperatures that kill organisms. While highly effective, this method can be energy-intensive and isn’t practical for all ship types, particularly those with limited energy resources.

- Acoustic (Cavitation Treatment)

Acoustic treatment uses sound waves to create bubbles in the water. When these bubbles collapse, they generate shock waves that destroy organisms in the water. This relatively new technology is still being developed but shows promise for use in future systems.

- Electric Pulse/Pulse Plasma Systems

Electric pulse systems use high-voltage electric fields to break down organisms’ cell structures, killing them instantly. These systems are fast and chemical-free, but they require a lot of energy to operate, making them better suited to larger ships with the necessary power resources.

- Magnetic Field Treatment

Magnetic field treatment is still an emerging technology. It uses magnetic fields to interfere with the biological processes of organisms, rendering them inactive. Though promising, this method is still in the experimental phase and has yet to be widely adopted.

Factors to Consider When Choosing a Ballast Water Treatment System

When choosing a ballast water treatment system for a ship, several factors need to be taken into consideration. Here are some of the key things ship operators look for:

- Effectiveness on Ballast Water Organisms

The system must be able to effectively eliminate or neutralize harmful organisms to meet international regulations.

- Environment-Friendliness

The system should not negatively impact the environment. Chemical treatments, for example, need to ensure that any residual chemicals don’t harm marine ecosystems.

- Safety of the Crew

Systems that rely on potentially hazardous chemicals or high-voltage equipment need to have safeguards in place to protect the crew during operation.

- Cost-Effectiveness

The system’s operating costs, including maintenance, energy usage, and consumables, need to fit within the ship’s budget.

- Ease of Installation and Operation

A system that is easy to install and operate is highly desirable, particularly for retrofitting onto older ships that may not have been designed with modern ballast water treatment in mind.

- Space Availability on Board

The physical space required for the system is a major consideration. Larger systems, like thermal treatment, may not be feasible for ships with limited space.

The Role of Filtration in Ballast Water Treatment

Filtration is often the first step in treating ballast water. This system uses physical barriers to capture larger organisms and particles before the water undergoes further treatment.

Filtration helps reduce the load on other treatment methods, making them more effective and efficient. However, because filtration can’t capture microorganisms like bacteria and viruses, it’s typically combined with disinfection methods such as UV or chemical treatment.

Automation in Ballast Water Treatment Systems

Automation plays a vital role in modern ballast water treatment systems, improving their efficiency and safety. Automated systems can monitor water quality in real-time, control the treatment process, and ensure that the system complies with international standards.

Automation reduces the need for human intervention, making the systems safer for the crew and reducing the chances of human error.

Adapting Treatment Systems to Different Ship Types

Ships come in all shapes and sizes, and so do their ballast water treatment needs. For example, a small fishing vessel will have different requirements compared to a massive container ship. Treatment systems need to be adaptable to the ship’s size, available space, and ballast tank configuration.

Some systems, such as UV or chemical treatments, are compact and easier to install, while others, like thermal or electric pulse systems, require more space and energy.

Maintaining Ballast Water Treatment Systems at Sea

Maintaining a ballast water treatment system is crucial to its proper functioning. Regular checks and cleaning ensure that the system doesn’t get clogged or suffer from malfunctions, especially in filtration systems. Automation can help alert the crew when maintenance is required, but it’s still important for the crew to be trained in basic upkeep.

By performing regular maintenance, ships can avoid costly repairs or fines for failing to comply with ballast water discharge standards.

Conclusion

Ballast water treatment systems are essential for protecting the marine environment from invasive species. By using a combination of technologies such as filtration, UV treatment, chemical disinfection, and more, these systems ensure that ships can safely discharge ballast water without harming local ecosystems.

Choosing the right system depends on several factors, including the ship’s size, available space, budget, and the regulations the ship needs to meet. With advances in technology and a growing focus on sustainability, ballast water treatment systems are becoming more efficient, automated, and environmentally friendly.

Whether it’s a small fishing boat or a massive tanker, every ship must take ballast water treatment seriously to safeguard our oceans for future generations.